© 2020 Black Diamond Engineering, Inc. All Rights Reserved.

Software Overview

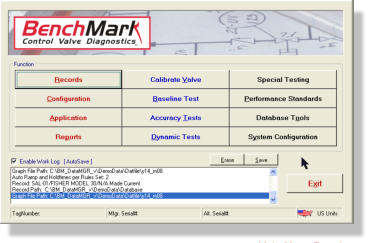

Main Menu

All BenchMark test, data management and system configuration functions are accessed from this straight-forward interface that has been designed for operators of all skill levels. Twelve command keys direct the operator to the various system functions. An automatically recorded log documents the work performed for quality control and maintenance records. BenchMark communicates with pressure (p/p), analog (i/p) or digital input valves positioners and tests control valves from all manufacturers.Valve Record Management

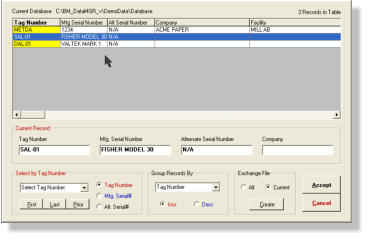

BenchMark valve data can be stored on any path accessible to the computer and can be organized by facility, unit, customer or in any other manner desired by the user. Individual valve records are quickly and intuitively located by tagnumber, manufacturer serial number or by a user defined alternate designation of up to 15 characters, numbers or symbols. Scan and select valve directly from the Identification table or select from a drop-down list configured to meet your preferences. If the valve has a BD MIT maintenance tag, the record can be loaded or accessed automatically. Once a valve record is made current, all other program functions have access to the valve’s detailed identification, configuration, application and test history.Valve Configuration

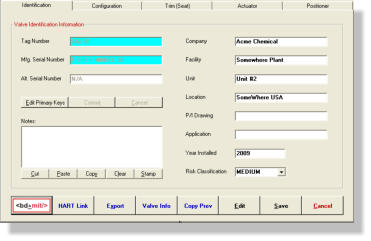

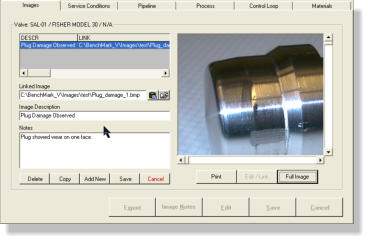

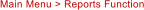

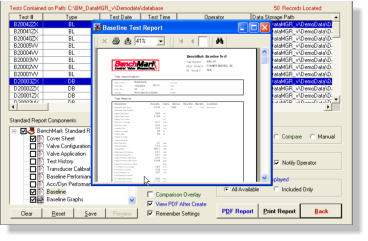

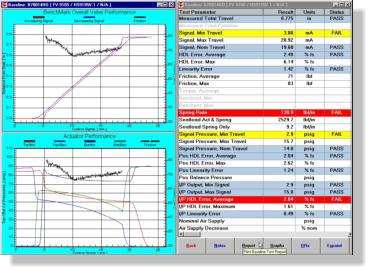

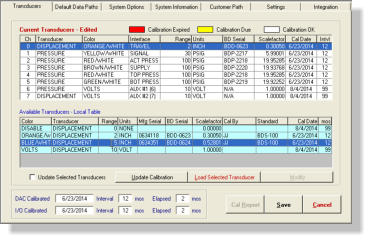

Detailed Configuration records containing the specification information for the control valve are easily accessible for the current record. Fields are logically organized in Identification, Configuration, Trim, Actuator and Positioning System pages each containing a Notes field that will accept virtually unlimited data. Wherever possible, data entry is by selection from customizable drop- down menus. Menu items listed can be readily modified by the user to reflect the unique inventory of valves in your facility. Additionally, selection can be made from customizable catalogs containing detailed information about Actuators, Packing Friction and Range Springs. Valve Application Detailed Application records containing the valve’s service application information are easily accessible for the current record. Fields are organized by Images, Service Conditions, Pipeline, Process, Control Loop and Materials pages. Each page contains a Notes field that will accept virtually unlimited data. Reports Whether your customer are plant managers, maintenance supervisors or control engineers, they will appreciate getting important problem-solving information without being buried in a pile of confusing reports, charts and graphs. BenchMark ‘s report generator lets you select the exact report elements to be printed or converted to a multi-page pdf format (portable document format - ideal for email communications). Documents can be previewed with a simple click of the mouse. Double - click any test to present test results and graphs for review, export or print. Performance Tests BenchMark includes all of the tests needed to evaluate the “health” of an air-operated control valve. During each test, real-time graphs keep you informed of the test status and valve performance. At test completion, engineering parameters with “Pass/Fail” comparisons are clearly presented. Automatically formatted graphs are used to clarify test results where appropriate. Test reports and full page graphs are immediately available for print, preview or export. All graphs can be enlarged, customized, zoomed and exported. Performance Standards BenchMark automatically establishes unique performance standards, based on the customizable rules, for each valve tested. These default standards can be easily modified to meet the special requirements of each customer and each valve. Define and set them one time. Standards for each engineering parameter can be enabled or disabled at your selection. At the conclusion of each test, results are compared to appropriate performance standards and “Pass / Fail” reported for that parameter. No more guessing about whether a result is too high or too low. Database Access / Menus / Catalogs BenchMark uses the power and flexibility of relational data tables to store valve information, perfornance standards, test history and test data. For normal testing and record management, access to these tables is conveniently managed for you. Access is provided to all tables used by BenchMark. You can use this tool to manage your Menu and Catalog content. For the end-user with custom data requirements, a powerful database access function is provided. Tools are included to retrieve test data by Standard Query Language (SQL), sort, filter, print and export the data in most popular formats. System Setup BenchMark uses the latest technology to increase operator productivity. No difficult transducer setup or complicated scalefactor calculations are required to use this state-of-the-art data acquisition system. Simply indentify the colors of the transducers in use and test. A complete table of calibration dates. scalefactors, serial numbers and more are just a mouse click away. Test data storage paths are managed automatically, but can also be selected manually. Similarly, test duration, ramp times and stabilzation times are set automatically according to customized rules. BenchMark easily integrates into Business Information or Asset Manager systems by importing task files in most standard file formats and exporting data files and reports in formats that can be integrated back to the business database.

Complete

Independent

Solution